by Ron-Son’s Torch

There are some things that are invented that we’ve never seen, just heard about it, but we instantly know how it can greatly help us. I was young when I first heard about this new invention called a microwave.

We were told it could cook a hot dog wiener in 45 seconds. To a young kid, that sounded like something from Star Trek. And your mind begins to race wondering what other things can you zap.

But despite its obvious appeal we weren’t the 1st owners of a microwave -too expensive.

Strangely enough, there are some similarities to that long ago event and inductive heating. If you’re doing any welding that requires pre or post heating – and you’re using a heating torch or ceramic tiles – then you might be interested in inductive heating…

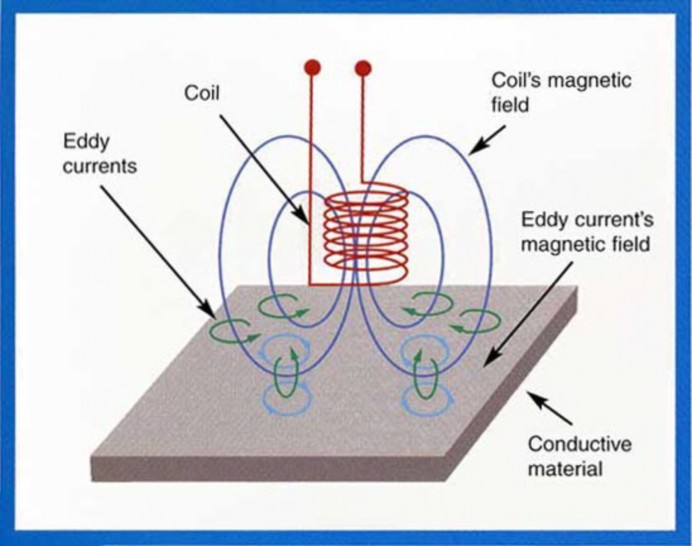

We know that whenever electrical current is flowing, a magnetic circle is created. If AC current is used, the magnetic field will be constantly reversing. Next, place a conductive material (like metal) within the magnetic field. The magnetic field sends eddy currents through the metal. The metal is going to be resisting the eddy currents.

Here’s where you begin your applied science. We can speed up the heating process by increasing the frequency of the AC current. The best part is that the heat happens inside the metal: small loss of heat.

Inductive heating’s best features are where the heat goes and where it doesn’t go. It’s like the microwave: the heat is in the wiener not in the microwave. Induction heating puts the heat in the material not in the tool.

Two most common ways of heating metal is with: resistance heating (ceramic tiles) or a heating torch.

(resistance heating, with ceramic )

heating torch

For both methods, the tool must first get hot. The tool then transfers the heat on to the surface of the metal. The direction of the heat is from outside, going inwards. But because you’re starting on the outside of the metal, some of the heat will be lost in the atmosphere. Inductive heating is the opposite: the heat is inside the metal and working towards the surface.

Ceramic tiles and the heating torch require safe handling practices. Ceramic tiles take time to cool down. If you want to move them before they are cooled down than some plan has to be made to deal with the heat (e.g. high heat gloves).

The heating torch has a lot of risk attached to it: flames shooting out the end, mixing of oxygen and fuel gases, hoses lying around your feet, gas cylinders to navigate, heating of the atmosphere, etc.

Heating up metal with a torch gets quite involved. First someone has to be holding the torch. Then he needs to know when the material is at the correct temperature. Once he removes the torch, a plan has to be in place to deal with loss of heat. There is no insulation to keep the heat within. It becomes more complicated if the part needs to be rotated.

Induction heating has the ability to heat to the temperature you want, hold the temp for the desired length of time, and cool it down in a timed manner.

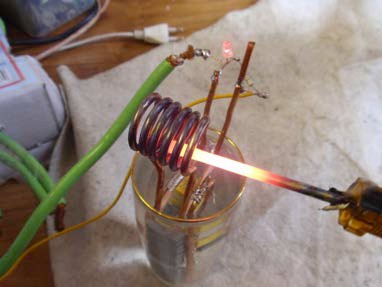

Whereas, induction heating uses cables that are cooled by air or water, allowing them to be handled at anytime during the process.

Not only can it be done in a controlled manner but without anyone having to monitor its work.

Inductive heating uses cables. The cables wrap around the material that needs to be heated. You can use plastic or rope to hold the cables in place – remember the cables don’t get hot; the metal gets hot. Probably the thing that requires most effort is learning how the cables are to be held and how far part they need to be, to maximize the heat.

Induction cables can be air or water-cooled. Air-cooled cables can heat the material to 400F and water-cooled cables up to 1450F.

Induction cables can be air or water-cooled. Air-cooled cables can heat the material to 400F and water-cooled cables up to 1450F.

The depth of heating depends upon the frequency. A high frequency heats close to the surface and low frequency penetrates deeper into the material.

Induction heating works on valves, pipes, etc.

Those who do a lot of preheating and/or post heating will be most interested in inductive heating. The superiority over the other methods is considerable.

Unfortunately, those who don’t do a lot of preheating probably will continue with alternative methods – because like the 1st wave of microwaves, they were a desirable but an expensive way to heat up your hot dog.

If we can help you or need more information, feel free to give us a call at 604-888-4481.

We’ll be glad to help you.

Cheers,

Ron-Sons Torch Repairs & Sales