Costs! What does it actually cost to make one widget? That’s never a simple answer. There are direct and indirect costs. There are costs that decrease (or increase) the more widgets you make. There are fixed costs and there are variable costs, and there are opportunity costs: could you have used your resources in an even better way?

When you know your costs then you can find efficiencies in manufacturing. This is why companies are buying software for their welding departments, they want to measure things that in the past went unmeasured (or were poorly measured). The software shows them how much it actually costs to weld a part. From those actual costs they create benchmarks. From those benchmarks they can measure the effectiveness of their new strategies.

While there are improvements in measuring costs there are still those that go unnoticed. In the AWS Welding Handbook Vol. 19th Edition, Chapter 12 Economics of Welding and Cutting is the heading Unforeseen Costs: Overwelding

What is Overwelding?

It’s when more welding wire is being deposited than is required. E.i. The drawing asks for 3/16” fillet weld and a ¼” weld was made.

Why Should We Care?

In most things, an extra scoop of ice cream for the price of 1 is a sweet deal. But in welding, the extra scoop is not welcomed. Extra deposit of welding doesn’t contribute anything to its strength and excessive welds can lead to a number of weld faults.

The extra convexity in the weld tends to produce notch effects and can lead to increased distortion. We won’t mention the person(s) who did a lot of work to arrive at the choice of weld, the size of weld and the length of weld. They had to calculate the needed strength, the performance of the part, the thickness of the metal and the type of joint.

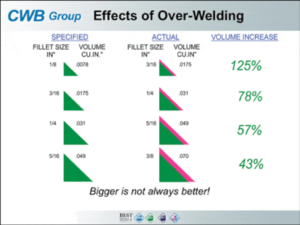

But here’s the real crime: real money is stolen and goes unreported when you overweld. Below is a chart from the Canadian Welding Bureau showing the effects of overwelding. It only shows the percentage of increase. You have to supply the numbers to calculate the extra cost of the wire, the extra gas and extra labor to overweld.

How Does Overwelding Happen?

The AWS lists four things that contribute to overwelding.

• Inaccurate cutting and fitting

• Poor supervision

• Insufficient training

• Lack of confidence in the strength of the weld.

How Do you Fix Overwelding?

First, you have to know whether the problem exists or not. In the majority of cases, overwelding doesn’t break any rules in the welding code. If the code isn’t going to red flag the issue, then it becomes a management issue. Management has to say it’s Not Acceptable and solutions need to be found.

The easiest solution is to supply the welder with a fillet gauge to measure his welds. Mock-ups can be made to show the proper weld. Additional training. The welding supervisor (or Quality Control) need to be having more oversight.

The solution doesn’t involve purchasing any new machines or trying new gases or running tests on the newest welding wire. Just weld what the drawings say to weld. And this unforeseen cost will go away.

If we can give you a hand in becoming more efficient, contact us.

Cheers,

Ron-Son’s Torch